OUR SYSTEM – FIRE RATING

We have 4 options for our aluminium panel finishes including:

Anodised Aluminium Panels – EU Class A1

FF3 Pre Coat Aluminium Panels – EU Class A1

Polyester Powder Coating – EU Class A2–s1,d0 (25-year warranty)

Polyester Powder Coating – EU Class A1 (25-year warranty)

The following data sheets are for each system component and have relevant fire information highlighted in yellow.

DATA SHEETS

OUR SYSTEM

Our proprietary high-quality overcladding is a pressure-equalised, back-ventilated, insulated aluminium rainscreen cassette system secretly fixed to an aluminium framework which is secured to the existing structure by stainless steel connections.

The rainscreen is integrated with high-performance windows by aluminium window pods and readily interfaces with other systems including curtain walling using proprietary extrusion profiles.

This system has BR135 classification, CWCT accreditation and is proven for more than 30 years, during which time severe fire has occurred and been successfully contained. The system comprises only inert aluminium and stainless steel fixings with anticipated service life well in excess of 60 years.

For overcladding to be successful it must last a very long time and provide modern desirable accommodation. The design build facades system is proven to last and continue to look good for the duration of its extended life, retaining its ‘as-new’ appearance without the need for periodic maintenance.

PROVEN IN-SERVICE FIRE PERFORMANCE

“Since the installation of the overcladding there has been a serious fire on Block A at deck access level. The fire whilst breaking out onto the façade through the glazing was successfully restricted to a small area of the façade and failed to move beyond the installed fire barriers.”

Extract from Parliamentary Select Committee – Appendices to the Minutes of Evidence regarding Hyde Park (a residential tower block overclad with design build façade’s rainscreen system)

BR135 CLASSIFICATION

To provide further reassurance to our customers, we are pleased to provide details of the successful BR135 fire test carried out at the BRE Garston.

Summary of Test Results

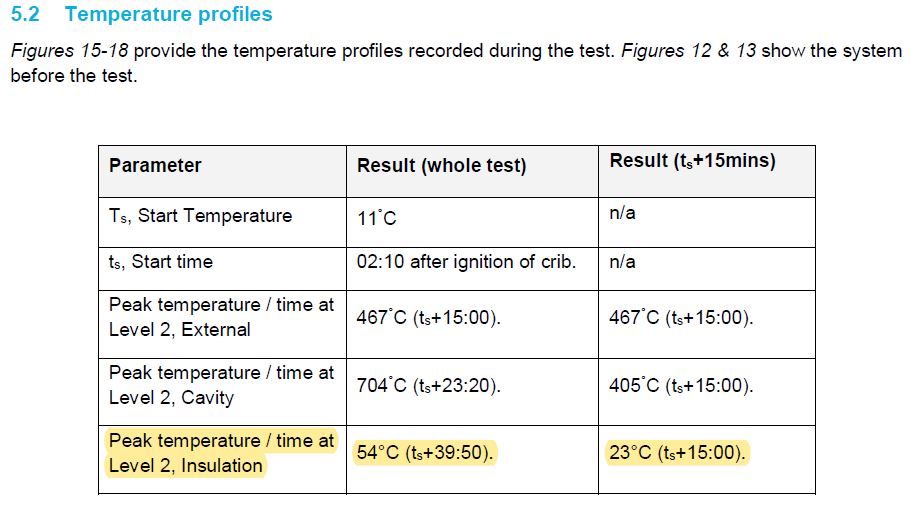

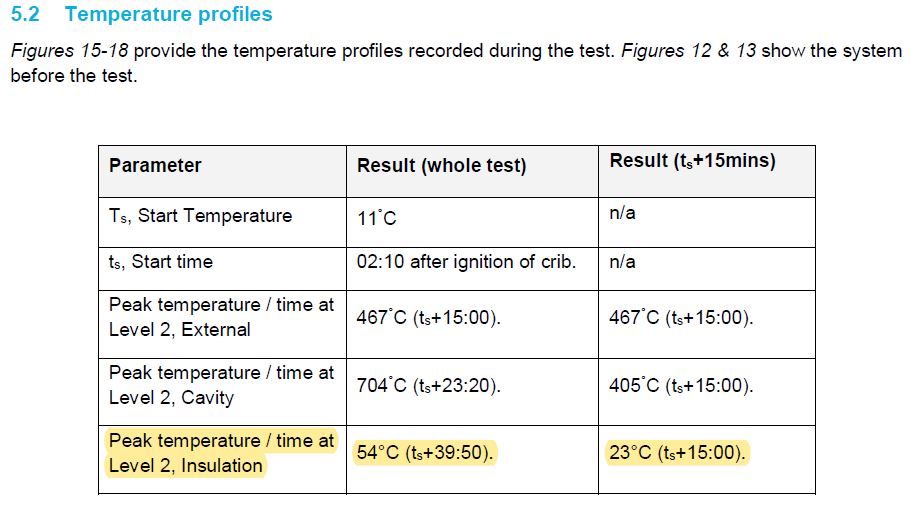

Please refer to the document ‘BR135 Performance Criteria’ document above which states that there are three criteria against which the system is evaluated: –

Test Criteria Explanation Test Result External Fire Spread No external level 2 thermocouples to exceed 600oC for a period of 30 seconds within first 15 minutes of fire Max temperature reached within first 15 minutes of fire 467oC (see item 5.2 of test report) Internal Fire Spread No internal level 2 thermocouples to exceed 600oC for a period of 30 seconds within first 15 minutes of fire Max temperature reached within first 15 minutes of fire 405oC (see item 5.2 of test report) Mechanical Performance No system collapse or ongoing combustion following the extinguishing of the fire No ongoing combustion or system collapse, flaming debris etc (see item 4.3 of classification report)

Key to note is the level thermocouple reading from within our insulation. Whilst the external fire reaches temperatures of over 1000oC (see graph 9.5 of test report) the temperature at the midpoint of our insulation never exceeds 54oC & only reaches 23oC within the first 15 minutes of the fire: –

CWCT ACCREDITATION

We are pleased to provide details relating to the successful testing of design build facades’ system to CWCT Standard Test Methods for building envelopes, 2005. This test confirms the weather tightness of the system in relation to air permeability, water tightness (static pressure, dynamic pressure and hose), wind resistance (serviceability and safety) and impact resistance.